Vagabond Kayaks founder and mechanical engineer Celliers Kruger offers a tutorial on how to combine foaming agents and polyethylene on their quest to find the perfect balance between durability, stiffness, and weight.

Materials used to manufacture kayaks have come a long way since the days of sealskin on driftwood frames. While there are still new designs based on the skin on a frame concept with modern materials, the vast majority of kayaks today are made from composite materials or plastic.

Composite materials have the upper hand when it comes to stiffness and weight, but there is no doubt that plastic, in general, is the more durable and more affordable option. Plastic kayaks are made by three different processes, each with different advantages and disadvantages.

Blow molding (used by Prijon and a few others) is a process that has stood the test of time. Blow-molded kayaks can be made of polymers like HTP, a very stiff and durable polyethylene. The downside is that the molds are prohibitively expensive. The nature of the process also has limitations on the shapes and features possible to mold.

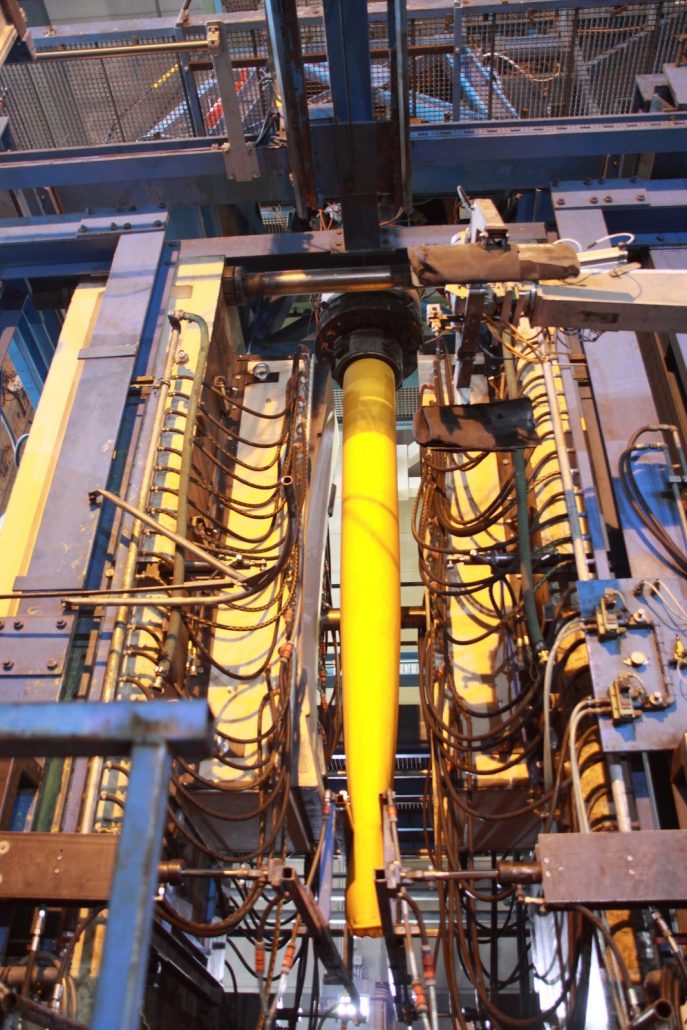

Prijon Blow Molding process ©Prijon

Thermoforming, on the other hand, utilizes a variety of different thermoplastics, such as ABS, to create stiff and durable kayaks. Delta, Native and a few other kayak companies use this process. The technology and materials come at a price though (literally), and it also means that where the two halves of the kayak join there is always an actual “split-line.”

THE MOST INTERESTING DEVELOPMENT IN THE QUEST IS THE USE OF FOAMING AGENTS

The majority of plastic kayaks are made through rotational molding, or rotomolding. The advantages of rotomolding are numerous. It is possible to mold complex shapes, the aluminum molds are relatively inexpensive (compared to other plastic processes), and the material is affordable.

The main disadvantage is that very few types of polymers can be successfully used. The polymer that is the mainstay of kayak manufacturing is LLDPE (Linear Low-Density Polyethylene). LLDPE is a tough and durable material; qualities that resonate well with kayakers. It is quite flexible though, which explains why rotomolded kayaks tend to be on the heavy side. Wall thicknesses have to be beefed up to create sufficient stiffness. The holy grail for rotomolded plastic kayak manufacturers is to find the right balance between durability, stiffness, and weight.

The most interesting development in this quest is the use of foaming agents to create a double or triple-layer kayak shell that combines the durability of PE with the stiffness and weight saving of foam. In this process, the first step is to rotomold a solid LLDPE skin.

Rotomolders with good process control can mold a thicker skin where high wear is expected, with a thinner skin where the focus is mostly just on dimensional stability.

The second step is to rotomold a second layer of LLDPE that has a foaming agent mixed into it. Once the layer has been molded, the foaming agent is activated. The resultant expansion of the foaming agent creates a foamed LLDPE layer that is highly rigid and also buoyant. It is a difficult process to master, but, if done correctly, the foamed PE has a closed-cell structure, and it is perfectly bonded to the solid LLDPE skin.

Sometimes a third layer of solid LLDPE is added to sandwich the foam layer, creating a perfectly smooth inside surface. This is often used in open canoes where the surface finish on the inside of the boat is just as important as the outside. Most rotomolding companies stay away from this foam system as it is notoriously difficult to achieve consistent results with the process. Those who use it do so for different purposes.

Thermoforming kayak in the making ©eddyline kayaks

Some use it to create lighter kayaks at the expense of long-term durability by making the outside solid PE skin relatively thin and using the foam to create the bulk of the rigidity.

THE ONLY DISADVANTAGE OF THE FOAM SYSTEM, IS THAT IT DOES NOT HANDLE POINT-LOADED HIGH IMPACT VERY WELL

Other companies use the foam layer to create kayaks that weigh the same as standard kayaks, but with the added advantage of much higher stiffness. The added stiffness increases performance on the water, reduces oil canning, and creates extra buoyancy that makes the kayak virtually unsinkable even if it fills with water.

The only disadvantage of the foam system is that it does not handle point-loaded high impact very well. For this reason, the foam system is not appropriate for use in whitewater kayaks where impact of this sort is part of the game.

Because of the difficulty in getting consistent results with the foam system, many companies that use the technology only offer it is as an extra, for which there is an additional charge.

At Vagabond Kayaks, launched at PADDLEexpo 2018, we have chosen to make foam technology the standard on all of our sit-on-top kayaks, from those designed for small kids to double-seater family sit-on-tops.

Committing to the application of foam LLDPE technology enables Vagabond to achieve one of our goals: offer kayaks of high quality to a market currently inundated by cheaply produced kayaks.

As to the why? We are in this for the long run, and we want our customers to enjoy not only our innovative designs but also the extended lifespan of our kayaks.

It will be a game changer to have this technology applied on such a scale, and will hopefully put the pressure on other companies to raise the bar when it comes to committing to quality.

Now the question remains, who else will follow suit?

By Celliers Kruger, Vagabonds kayaks Founder.

More info on vagabonds kayaks, go to http://vagabondkayaks.com/

This article was first published the 2019 PADDLEexpo Buyers Guide